Higher lubricant standards deliver up to 5 years longer operating life

Technologically right on the industry pulse and grounded in real-life operations – the Oil Laboratory of the International Association for the Generation and Storage of Electricity and Heat (vgbe) has been analysing lubricating and insulating oils for over three decades. Based on this deep expertise, the Laboratory has defined its own demanding certifications that go well beyond common industry standards and deliver measurable benefits to industrial operators.

Within the vgbe, over 1,600 employees at international companies in the industrial and energy sectors contribute their expertise in over 80 specialist committees. OEM machine builders and component suppliers are also involved in this highly specific work as members of expert working groups. The guidelines defined by the vgbe have made a major contribution to operating power generation plants more reliably, more efficiently and more sustainably in environmental terms. This work is especially important when it comes to supply security.

The Standard that makes a performance difference

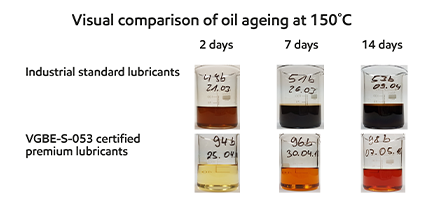

High-performance lubricants are a vital factor in efficient power-plant operation. This is why the vgbe Oil Laboratory has developed the VGBE-S-053 Standard, a certification for lubricants which reduces the frequency of oil changes as well as resource consumption, increases operating safety and improves the operator's CO2 footprint. In particular, the superiority of VGBE-S-053 certified oils is evident in their ageing behaviour as well as their air and water separation performance.

| Property test | DIN 51515 oils | VGBE-S-053 certified premium oils |

|---|---|---|

| Air-separation limits | 5 min | 1-3 min |

| Water-separation limits | 300 sec | 60-200 sec |

VGBE-S-053 certified oils enable two to five additional years of operation per oil fill. Depending on operating conditions, this means up to three fewer oil changes over the operating life of the plant.

Crème de la crème: Mobil oils for steam and gas turbines

Mobil SHC™ 800 Ultra Series oils are specifically developed for turbines and are certified to the strict VGBE-S-053 Standard. Operators can benefit from reduced plant downtime and maintenance costs, higher plant availability and greater power-generation efficiency.

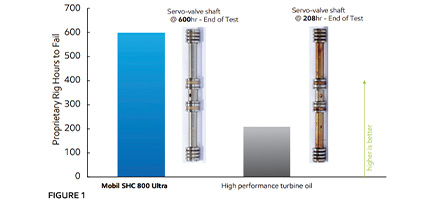

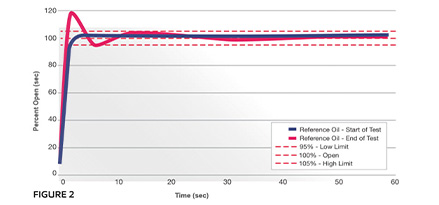

The trend towards smaller oil tank volumes, compounded by higher tank and oil storage temperatures, is placing increasing demands on turbine lubricants. Aggravating this is cost pressure, sustainable resource consumption requirements and supply-security concerns. The Mobil SHC™ 800 Ultra Series is specifically engineered to meet these challenges. This Series of oils meets and often exceeds the requirements of many OEM turbine manufacturers, provides outstanding oxidation stability, prevents deposits e.g., in servo valves, and demonstrates excellent air and water separation values. Figure 1 shows the negligible varnish levels on a valve plunger when using the Mobil SHC™ 800 Ultra series:

Increased operating lifetime & optimal deposit control

Independently tested and practice-proven

Reliable plant protection and outstanding operating performance are two reasons why Mobil SHC™ 832 Ultra and Mobil SHC™ 846 Ultra turbine oils have been certified to the demanding VGBE-S-053 Standard by the vgbe Oil Laboratory. Achieving this accreditation is significantly tougher than meeting DIN 51515 and comparable industry standards. Oils such as Mobil SHC™ 846 Ultra have already proven their advantages in many power-generation plants and have helped operators achieve savings of tens of thousands of euros thanks to reduced plant maintenance intervals and higher plant availability.