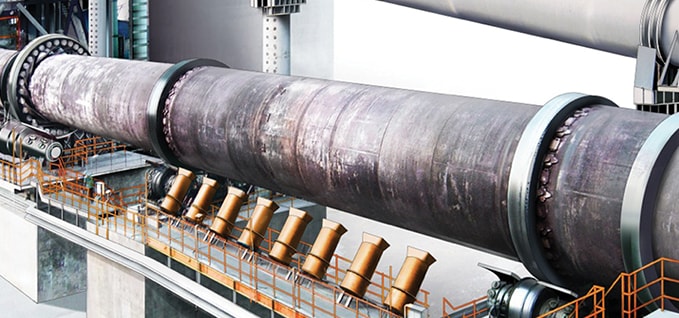

Success stories and industry insights

Synthetic grease helps eliminate oil leaks and prevent production loss

Transitioning to Mobilith SHC 460, the Egyptian cement company was able to reduce downtime due to bearing failures and repairs, as well as oil consumption with savings of more than US $1,000,000 per year

Synthetic gear oil helps cement producer reduce power consumption

After transitioning to Mobil SHC Gear 320 synthetic gear oil, Chinese Cement company was able to reduce operating temperatures by 5°C (9°F), as well as reach record-low power consumption levels

Synthetic grease helps cement plant reduce energy consumption and extend lubrication intervals

With help of Mobilith SHC 100 operating temperatures on the roller press were reduced by 44°C enabled productivity savings estimated at US $176,700 based on the elimination of external cooling, reduced maintenance costs and grease consumption.

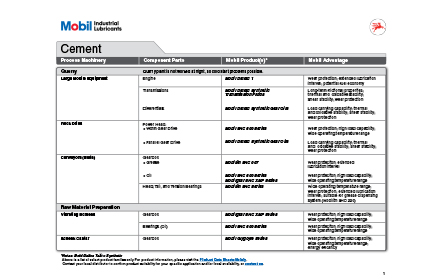

Explore related products and applications for your cement business

Enclosed gears

Our Mobil SHC™ Gear synthetic gear oils protect industrial gearboxes and help extend oil life in some of the most extreme conditions.

Mobil SHC™ 600 Series lubricants are exceptional performance gear and bearing oils designed to provide outstanding service in terms of equipment protection, oil life and problem-free operation helping to enable increased customer productivity.

Open gears

Mobilgear OGL 007, 009, 2800 and 461 are high performance advanced technology lubricants which incorporate both extreme pressure additives and finely dispersed graphite for load carrying.

Mobil SHC™ Gear 1500,3200,6800

The Mobil SHC Gear 1500, 3200, and 6800 lubricants are supreme performance heavy-duty gear oils primarily designed for all kinds of enclosed gearing as well as plain and rolling element bearings. Mobil SHC, Mobil SHC Gear, Open Gears, Gear Circulating System

Greases

For severe operating conditions, including high temperature and water contamination. 5% molybdenum disulfide provides additional protection

Multipurpose Calcium Sulphonate Complex Grease. The inherent EP properties exhibit great stability in the presence of water.

Hydraulics

HLP hydraulic oils for extended oil drain intervals & cut hydraulic oil costs. Reduced waste oil disposal improves environmental footprint.

Zinc-free, HVLP anti-wear hydraulic oils designed for the modern hydraulic systems. Energy efficiency potential, long ODI, clean valves.

Services that advance your business

Our experienced team are here to support you with your equipment servicing, every step of the way.

*Actual benefits can vary depending upon the type of equipment used and its maintenance, operating conditions and environment, and any prior lubricant used. Extended life and energy efficiency is based on normal use of the product, as described in the technical instructions from ExxonMobil