Mobilith SHC™ 100 synthetic grease helps cement plant reduce energy consumption and extend lubrication intervals*

Generated company-estimated

annual savings of US $176k

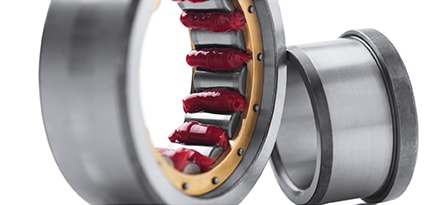

Roller press mill engine bearings

Cement plant

Colombia

Situation

A Colombian cement plant operates a roller press with bearings that were experiencing operating temperatures as high as 180°F (82°C), which resulted in the need for frequent regreasing. In order to help alleviate stress on the bearings at these extreme operating temperatures, the plant began cooling the machines with external air compressors. To help address this issue further, the company approached ExxonMobil for a lubricant solution capable of lowering operating temperatures and extending lubrication intervals.

Recommendation

ExxonMobil engineers recommended switching to Mobilith SHC™ 100 synthetic grease. Formulated with synthetic base oils and an advanced lithium complex thickener, Mobilith SHC 100 provides outstanding wear protection and lower frictional resistance under high temperatures. It’s excellent structural stability and adhesion are designed to reduce bearing leakage and the need for frequent re- greasing.

Impact

After transitioning to Mobilith SHC 100 synthetic grease, operating temperatures on the roller press were reduced by 80°F (44°C), mitigating the need for air compressor supplemental cooling jets. In addition, regreasing intervals were doubled, which reduced maintenance needs and the related safety exposure of maintenance personnel.

Benefit

The company reports that Mobilith SHC 100 synthetic grease enabled productivity savings estimated at US $176,700 based on the elimination of external cooling, reduced maintenance costs and grease consumption.

*This Proof of Performance is based on the experience of a single customer. Actual results can vary depending upon the type of equipment used and its maintenance, operating conditions and environment, and any prior lubricant used.